The race is over and we have lost. As far as lithium-ion battery technology goes, the Chinese have won. They set their sights on a product that they could excel at and now they own it.

China decided on this course very early

China has pursued a position of supremacy in the lithium-ion battery space since 2001, when the country made it a cornerstone of its Five Year Plan. After “inviting” their many joint venture partners into China and learning how to properly manufacture vehicles, there was a realization that they would not be able to out-innovate the Americans and Europeans when it came to internal combustion engine (ICE) vehicles.

This led to major government support for the development of an EV battery industry starting in 2009. This was something that the “foreigners” were not pursuing. From 2009 to 2023, the Chinese government poured a substantial $230 billion into both batteries and EVs. This took the form of inexpensive land, tax breaks, and other incentives. Top Chinese battery producers like CATL, BYD, CALB, and Gotion have reaped the benefits and dominate the battery market, in China and elsewhere.

Total control of the supply chain

In addition to the manufacturing of EV batteries, China has gained control of the entire EV battery supply chain. This includes materials found on its home turf as well as supplies on other continents.

Related: The 1970-72 Porsche 914/6 was the father of the Boxster and Cayman

Here’s one example: Partially or completely Chinese-owned firms will produce over 90% of Africa’s entire lithium supply for the next ten years! To make things worse, China’s EV battery production capacity already exceeds world demand by around 400%.

Is it any wonder Chinese EVs are so inexpensive?

This helps to explain how the Chinese can price their EVs so low – all of the materials going into the battery have been subsidized by their government. This gives them a pricing advantage, which when combined with the industry’s overcapacity, now has them shipping their EVs all over the world to various export markets.

Is there anything we can do to stop this?

While it’s pretty much game over as far as liquid electrolyte lithium-ion batteries go, we should not give up. We should be building our own lithium-ion battery plants and supply chains so that we can provide our EV industry with a stable source of batteries that cannot be cut off for political reasons.

The Inflation Reduction Act has already spurred a massive investment in American-based lithium-ion battery plants, making that goal a reality. Regardless, we should realize that lithium-ion batteries are reaching their performance limits and it’s time to go beyond them.

Related: Surprising military tech that revolutionized your car

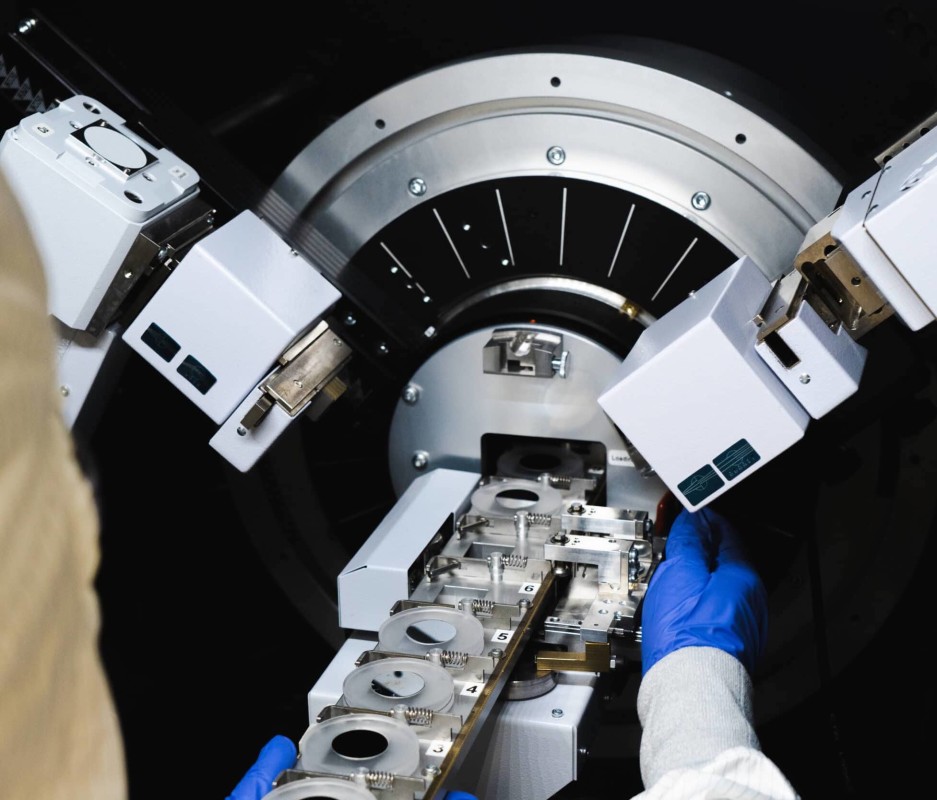

Moving forward, the real action is at the next level of EV battery development. And that’s solid-state batteries, for which we have not yet ceded development to the Chinese. It’s the best way to preserve our auto industry for the future.

Solid-state batteries will solve many of our EV problems

The next generation of solid-state EV batteries are the answer to many troubling issues we must live with in today’s electric vehicles. These solid-state batteries will charge faster, have more energy density and thus be lighter, and will be much safer than today’s lithium-ion cells, eliminating the possibility of thermal runaway. Even better, solid-state batteries need no graphite, which China has near-total control of.

Just imagine an EV with 1,000 miles of range, a five-minute charging time, normal weight, and low fire hazard. That would solve most of our EV adoption problems right there!

We need to get on the solid-state bandwagon now, while there’s still time

In order to reap a commercial advantage from the development of solid-state EV batteries, we must provide more funding for R&D, accelerate the commercialization of products that come out of the lab, and provide a protected environment (such as military-related projects) in which these batteries can be made ready for mass production as soon as possible.

The next race for solid-state batteries is on and we are not the only ones running in it. In addition to a Chinese-sponsored consortium including battery maker CATL and automaker BYD, Japan’s Toyota, Nissan, and Honda, and Korea’s Samsung are also hotly pursuing solid-state batteries. The big challenges facing all solid-state battery developers are making them at large scale while bringing the cost down.

Related: Hertz hosting a fire sale on Tesla rental fleet

Here in the U.S., the largest firm involved in solid-state batteries is QuantumScape, who already has a deal with the Volkswagen Group. But there’s not much time – Samsung is planning for 2027 production, while Toyota and Nissan are shooting for 2028. Honda is building a solid-state battery demonstration production line, with production planned sometime during the final half of the decade.

Final thoughts

It’s now or never. The Chinese have eaten our lunch where lithium-ion batteries are concerned, but we still have a chance to grab the lead in the solid-state battery race. The clock is ticking…